铝导管

铝导管CHARATERISTIC

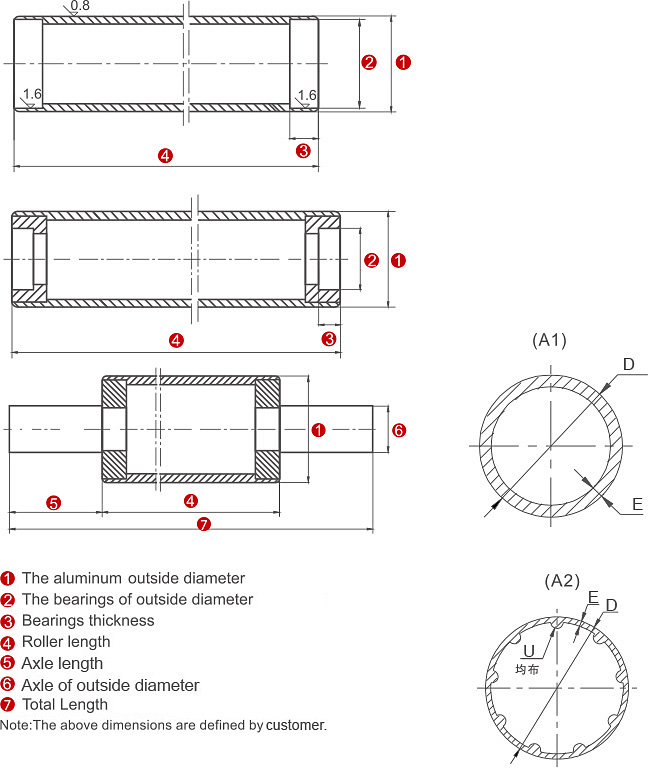

Aluminum guide roller (also known as "aluminum alloy guide roll") is made of high quality aluminum alloy materials, and it has all kinds of modules and sizes with ribs structure and the outside diameter is from 25mm to 320mm. Under the cheat by computer balancing correction process, the dynamic balance of the aluminum roller will be small than 2g. With using of sophisticated equipment and special tools, the roll surface gloss can be 0.8, concentricity can reach to 0.02mm. Special cheated in the shaft axle of the roller, with imported bearings, the aluminum guide roller works well even at high speed.

According to different industries, the surface of the roller can also do special treatment: Anodized HV300 treatment, Hard anodized HV700 treatment, Teflon treatment, to make the roller scratch, abrasion and anti-sticking.

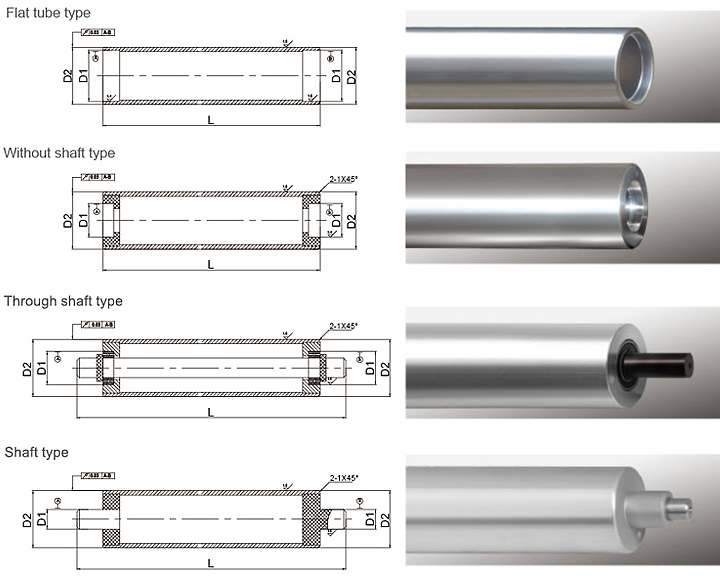

Aluminum guide roller has normally 3 standard types: Without-shaft type, Shaft type and Through-shaft type. The surface can treated by normally 3 standard line types: Center line type, Cross line type and Grooved type.

Chuangbo brand aluminum guide roller is high strength, low resistance, light weight, flexible rotation, no-rusty, wearable and corrosion resistance, especially suitable for printing, packaging, plastics, paper, glass, pharmaceutical, electronics batteries, textile machinery and industries.

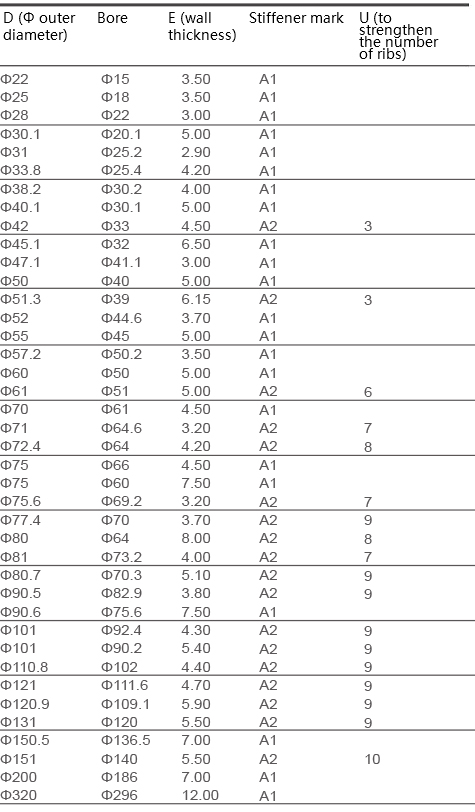

ALUMINIUM TUBE DATA

STANDARD STYPE

SURFACE TREATMENT OF REFERENCE

|

Anodic oxidation HV300 Silvery white

|

Anode hard oxidation HV700 Tan

|

|

Teflon Green Anti adhesion and corrosive

|

Mirror surface anode hard oxidation HV700 Tan

|

SURFACE TEXTURE